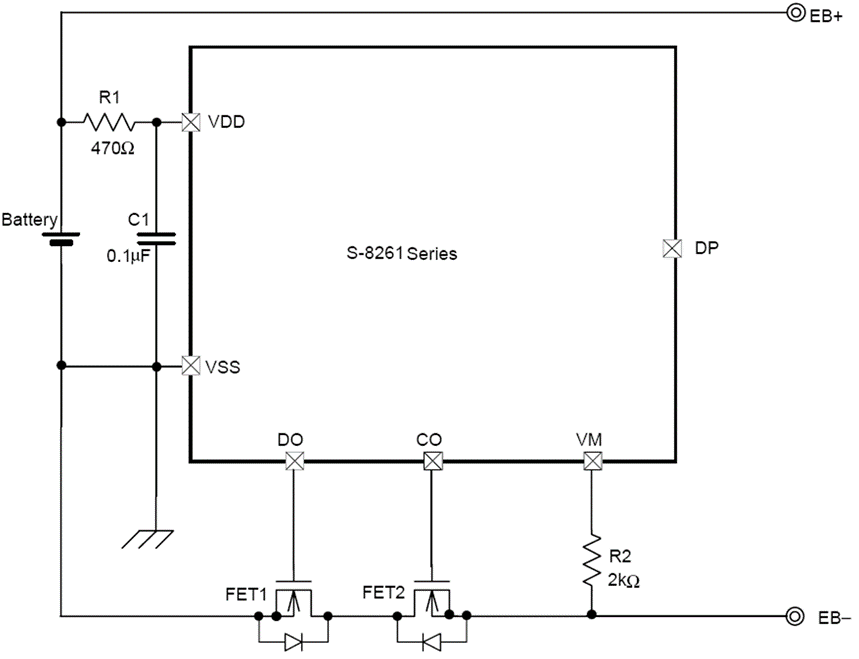

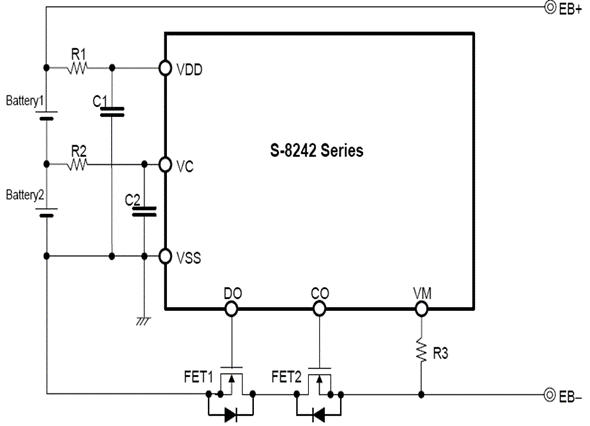

All rechargeable lithium batteries need to be protected. It requires protection from over-charge, over-discharge, over-current, short circuit, over-temperature, ect.

Main function of PCM:

a. Over charge protection, stop charge once reach to certain voltage, in another word, MOS that controls overcharge be cut off, stop charge.

b. Over discharge protection, stop load discharge when voltage drop to certain voltage, MOS that controls over discharge be cut off, stop discharge, it’s opposite with over charge monitor.

c. Over current protection, stop load discharge when over current too large, aim to protect battery and MOS, make sure the safety of battery when working; and PCM will auto recover.

d. Short circuit. Principle as below, protect IC, core of protect chip, judge from sample Battery Voltage, send control message to MOS, manage chip; MOS, switch of PCM circuit.

Main PCM supplier:

Demand of global market about 100 million per month

a. A grade market, 40 million per month, main protect IC manufacturer SEIKO, RICOH, MITSUMI; MOSFET manufacturer, SANYO, AO.

b. B grade market, 40 million per month, main protect IC manufacturer FORTUNE, NEOTEC, VIMICTO; MOSFET manufacturer, SAMHOP, CETSEMI, SOUTHSEASEMI, MAXTEK, ANPEC.

c. C grade market, 20 million per month, main protect IC manufacturer SILAN, SINGEN, JWK; MOSFET manufacturer ZHUHAI NANKER, SINGEN, JWK.

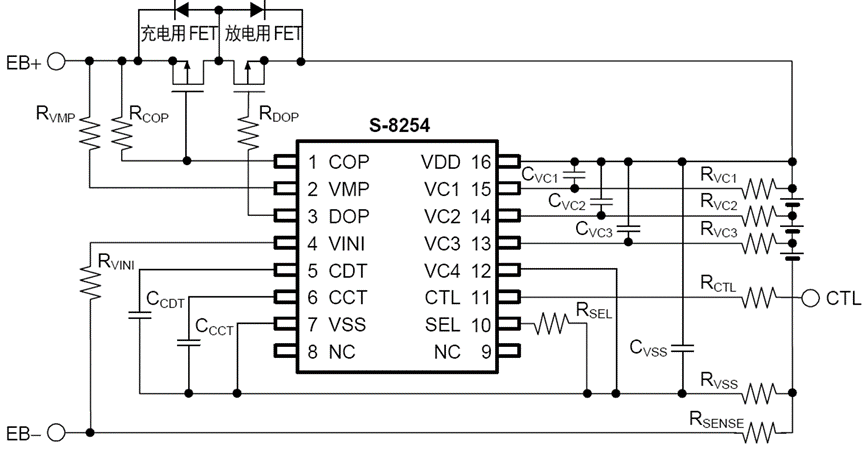

PCM Circuit for 3.7V battery pack:

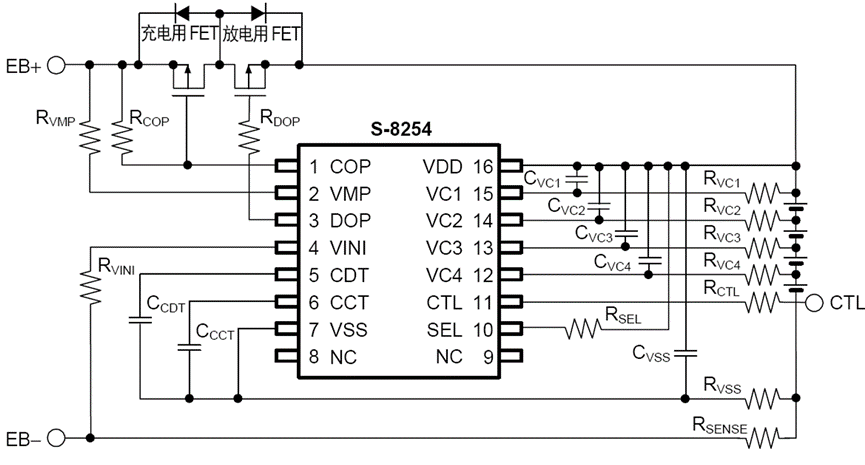

PCM Circuit for 7.4V battery pack:

PCM Circuit for 11.1V battery pack:

PCM Circuit for 14.8V battery pack:

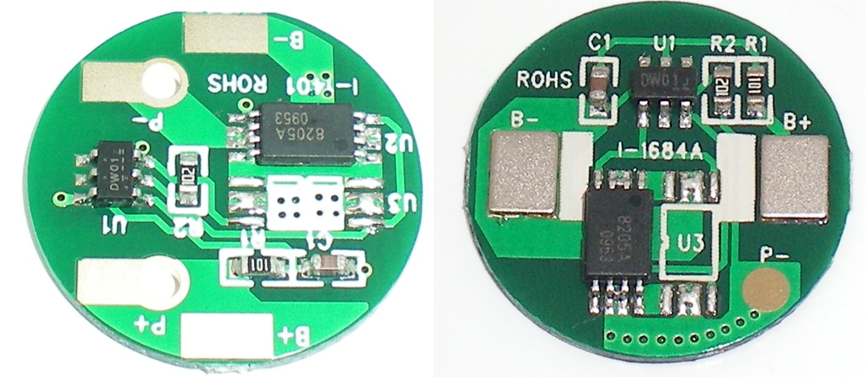

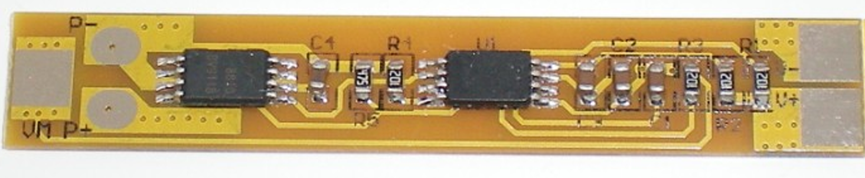

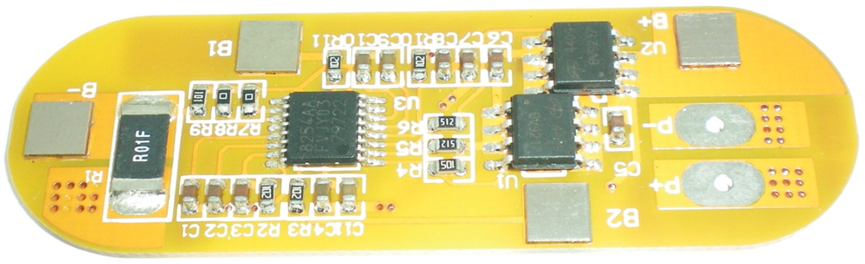

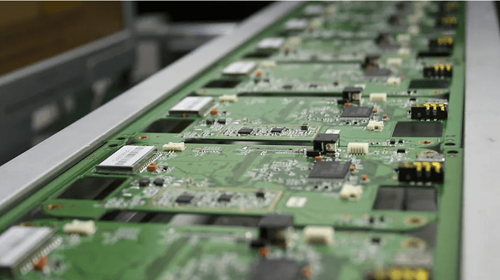

Physical image for PCM:

PCM for 3.7V 18650 battery

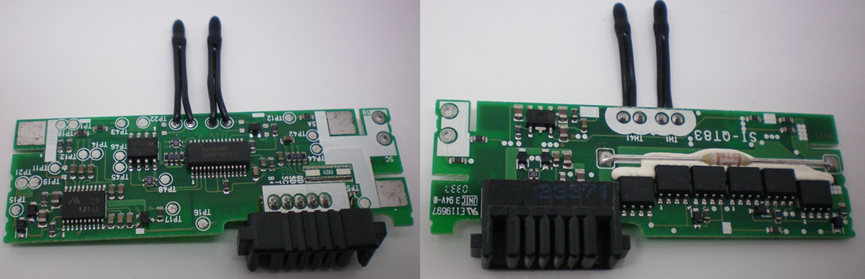

PCM for 7.4V battery pack

PCM for 7.4V battery pack with temperature control

PCM for 11.1V battery pack

PCM for 11.1V battery pack with SM-Bus communication

PCM for 14.8V battery pack

Partial PCM showed.

Our professional engineer will recommend suitable PCM according to the specs provided by you, such as pulse&continuous working current, discharge cut-off voltage, product name,ect.

Welcome to share us more information. We are glad to help you in further.

Be caution when assemble Lithium battery in serial and Parallel

Lithium battery in serial or parallel combination sounds simple, while to avoid quality problem, there is something you need to know.

Before combination, it requires to match battery with similar voltage, impedance and capacity. Voltage difference below 10mV, impedance difference less than 5mΩ and capacity difference less than 20mA.

If the voltage and capacity difference is big, lower voltage or zero voltage might happen. Because some lithium battery cell might be over-charged, while some are not fully charged when recharge. At the same time, some battery might be over discharged while some are not fully discharged. This will also do harm to the battery for long term.

Never use new and old battery in one combination. And do not mix cells with different brand or different capacity. Make sure use the same type of battery when combination.

Our professional team usually match the battery before combination. If you will assemble at your end, then please advise how many pieces in one battery pack. We will match according to your quantity.

1. Main material for Lithium ion battery:

Lithium ion battery mainly consists of five parts: Shell, anode, cathode, separator, electrolyte

At present, the main enclosures are:

Steel: cylindrical battery, square battery

Aluminum: square battery, cylindrical battery

Aluminum plastic film: polymer battery

1.1 Anode

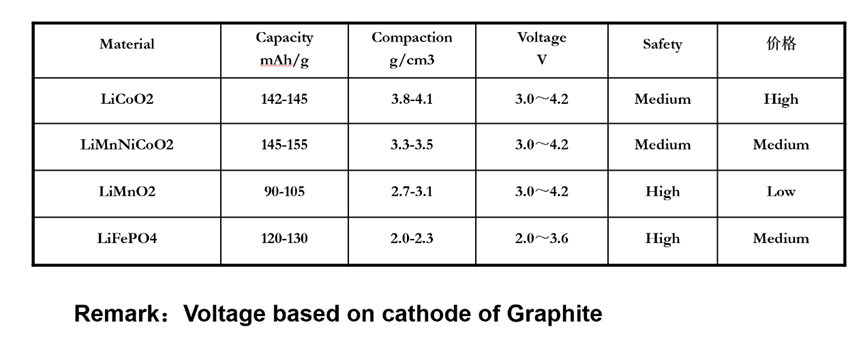

Main material used for anode: LiCoO2, LiMnNiCoO2,LiMnO2,LiFePO4

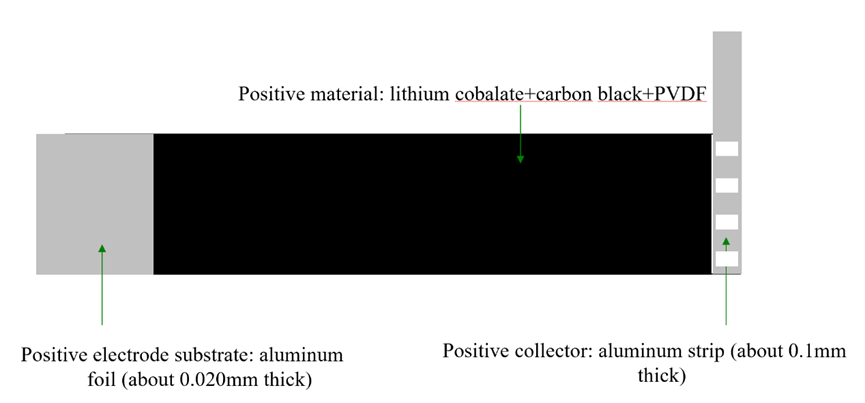

Positive pole structure of lithium ion battery (see view) :

1.1 Cathode

There are two kinds of cathode materials: graphite and lithium titanate

Graphite: At present, more than 99% of lithium batteries use this cathode material, with a capacity of 300-360mAh/g and a compaction density of 1.45-1.7g/cm3. It is mainly divided into natural graphite, artificial graphite and mesophase carbon microspheres.

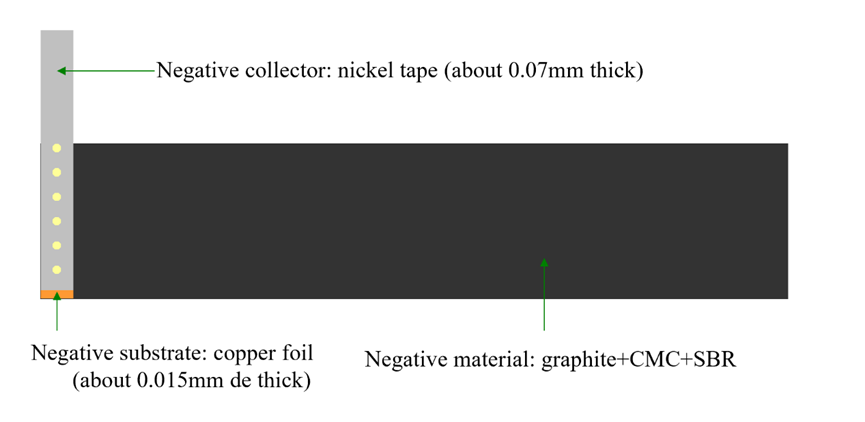

The cathode substrate is copper foil.

Lithium titanate: At present, only a few manufacturers are developing and applying it. Because of its excellent cycle performance, it is promising in the field of power batteries. At present, the problem is also very obvious. The charge discharge expansion is large. After being applied to lithium batteries, the voltage decreases by 1.0-1.2V compared with graphite.

Negative pole structure of lithium ion battery (see view):

1.1 Separator

There are two main types of diaphragms: wet diaphragm and dry diaphragm

Wet membrane: PP/PE/PP three-layer membrane represented by TONEN, ENTEK, ASAHI

Dry process diaphragm: PE single-layer diaphragm represented by CLGARD and UBE

Domestic manufacturers include wet Buddha plastic Jinhui PE, dry Grayne PP, etc. Their manufacturing methods are different from the above two

At present, the thickness of commonly used diaphragm is 12 μ m,16 μ m,20 μ m,25 μ m,30 μ m. In addition to the above, ceramic diaphragms are being used, which are based on the above diaphragms and coated with a layer of metal oxides, Al2O3, SiO2, etc. Such diaphragms are gradually used in high energy density and power batteries due to their strong puncture resistance and flame retardancy.

Material: single layer PE (polyethylene) or Three layer composite PP (polypropylene)+PE+PP

Thickness: 0.016 ~ 0.020mm for single layer

The third floor is generally 0.020 ~ 0.025mm

1.1 Electrolyte

(1) Solid polymer electrolyte: mainly used for making solid state batteries, which is still in the laboratory stage

(2) Gel polymer electrolyte: It is mainly used to make gel polymer batteries. At present, only a few companies use this electrolyte.

(3) Liquid electrolyte: at present, most batteries use this electrolyte;

Solvent: mainly carbonate, such as EC, PC, DMC, DEC, EMC, MPC, etc;

Solute: mainly LiPF6, others LiAsF6, LiBF4;

Additives: adding a small amount can significantly improve a certain performance or several performance of the battery, such as VC, PS, etc;

2. Working principle of lithium ion battery

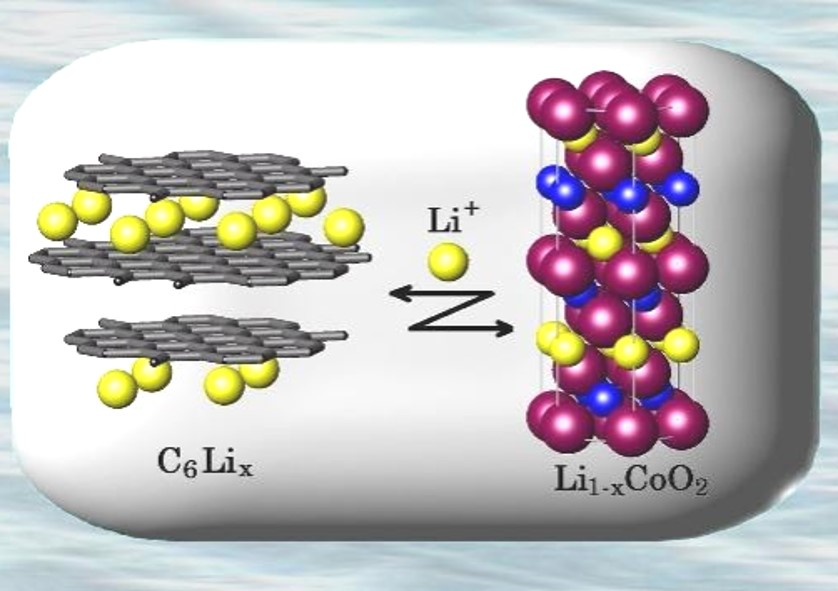

During the charging and discharging process of lithium-ion battery, Li+is embedded and de embedded back and forth between the two electrodes, which is known as "rocking chair battery".

When charging the battery, Li+is dis embedded from the positive electrode and embedded into the negative electrode through the electrolyte. The negative electrode is in a lithium rich state. The opposite is true when discharging.

Positive reaction:LiCoO2==== Li1-xCoO2 + x Li+ + xe

Negative reaction:6C + x Li+ + x e- === LixC6

Total reaction:LiCoO2 + 6C ==== Li1-xCoO2 + LixC6

3. Classification of lithium ion battery from shape

Prismatic, cylindrical, polymer

4. Main application for lithium ion battery

l Mobile lighting flashlight flashlight, HID flashlight, HID portable searchlight, diving light, emergency lighting, high-power LED lighting, film and television lighting equipment, etc.

l Medical instruments and equipment portable monitor, transcranial Doppler blood flow analyzer, ECG monitor, portable X-ray system, B-ultrasound instrument, respirator, infusion pump, blood gas/electrolyte analyzer, pulmonary function detector, rehabilitation instrument, etc.

l Military security monitoring industrial detection and measurement instruments Military wireless communication, PDL digital control radio, chemical agent detector, satellite positioning and navigator, wireless intelligent alarm, wireless monitor, communication cable detector, mapping instrument, etc.

l Portable printer, POS machine, automatic order machine, walkie talkie, wireless handheld monitor, wireless baby monitoring camera, GPS positioning system, handheld data terminal, portable projector, barcode scanner, etc.

l Electric tools toys electric cars rechargeable electric drills, screwdrivers, circular saws, reciprocating saws, sandpaper machines, rechargeable round forest tools, rechargeable electric scissors, rechargeable cutting machines, aviation and navigation models, electric wheelchair bicycles, golf carts, etc.

l Communication digital IT portable industrial control computer, PDA handheld computer, notebook, electronic reader, learning machine, electronic dictionary, digital camera, video camera, wireless music player, wireless headset, PSP game machine, etc.

l ODM/OEM battery mobile power combination battery intelligent cleaner, intelligent robot, intelligent toilet, warm clothing, wireless transmitter, air humidifier, solar energy charger, mobile power, backup photography power, etc.

Small battery used for:Bluetooth earphone,MP3,MP4

Medium battery used for:Cellphone,GPS,Digital camera/DV

Big battery used for:DVD,tablet

Other battery pack:RC toy,E-bike,power tool

We are professional battery solution provider. If you need help for power solution, please feel free to contact us.

It usually takes about 2~3working days.

SUJOR aim to provide customer medium higher level quality product, every battery from us will be strictly follow up at least five steps quality control reflected in R&D process, incoming control process, production process, prior-shipment control and after-sales service process.

If you have further doubt on battery formation, please contact us.

No. The battery can not discharge normally if there is no formation.

Formation is a critical production process for lithium polymer battery. The purpose is to active battery by charging the battery with small current. SEI film will generate on the surface of the negative pole, the battery performance will be more stable.

If you have the proper charger, charging lithium batteries is no different than most other battery types. Any charger from us, or any charger with an AGM Charging profile will work perfect. Standard lead acid battery chargers will not allow you to maximize the performance of lithium batteries. Due to their lower operating voltage, a standard lead acid battery charger may only charge your SUJOR Lithium battery to 60% to 80% of its full potential. We strongly recommend a LiFePO4 rated charger to get the most out of your batteries.

LiFePO4 batteries are very safe. Lithium iron phosphate has excellent thermal and chemical stability. These batteries stay cool in higher temperatures. They are also incombustible when mishandled during rapid charge and discharge or there are short circuit. Lithium iron phosphate does not experience thermal runaway in the same way that other lithium-ion batteries do, as the phosphate cathode will not burn or explode during overcharging or overheating as the battery remains cool.

With the increasingly stringent requirements for global carbon emissions and the energy shortage in European countries caused by the Russian-Uzbekistan war, the application of new energy, mainly represented by solar energy, has reached a climax. Solar power generation has serious instability. With the significant change of power generation in daytime and sunny days, the demand for energy storage becomes more and more important. As a basic small unit of life, household energy storage batteries have also become people's favorite. However, as a new product, what core components are included in the household energy storage battery, and how the current market situation of these core components is, this article will introduce in detail.

Although it is a household energy storage battery, it is basically the same as the battery for other purposes. It is composed of battery cell (battery monomer), battery management system BMS, housing case, input and output terminals, structural parts, etc. The voltage and capacity required by the household energy storage battery are solved through the series-parallel design of the battery cells. The battery cells are fixed in the chassis by combining the structural parts, and connected to the BMS and then connected to the input and output terminals. Finally, the required energy storage battery can be formed by packaging the chassis. Among these components, the real core is the battery cell and battery management system (BMS), which will be described as below.

1. Lithium ion battery

1.1 According to the chemical material system, lithium-ion batteries are divided into ternary lithium batteries and lithium iron phosphate batteries. Due to high chemical activity and poor safety performance, ternary lithium batteries are gradually replaced by lithium iron phosphate batteries with higher safety performance and longer service life in the fields of electric vehicles and household energy storage batteries. From a global perspective, except for Tesla TESLA and LG Chem, which use ternary lithium batteries for household energy storage battery products, other manufacturers have basically chosen the lithium iron phosphate battery route. Let the market lose patience and confidence in ternary lithium batteries.

1.2 Lithium iron phosphate batteries include three structural forms, namely: cylindrical batteries, square aluminum shell batteries and soft-pack batteries. As a finished household energy storage battery, it doesn’t care too much about the structure of its battery core, but many buyers will prefer a certain form of product due to misleading information, and even a few people think that lithium iron phosphate battery The core is the vague concept of the square battery. In fact, these three types of batteries can theoretically be used in household energy storage batteries, the key lies in the design of the structure, optimization of heat dissipation, cost control and other aspects. Most factories use square shell LiFePO4 batteries now. Because it has higher energy density than cylindrical battery and more easy to pack than soft-pack battery.

1.3 Quality for LiFePO4 battery cell

No matter what kind of battery cell, its quality level is uneven. Roughly speaking, the same model of the same manufacturer can be basically divided into three categories: qualified product (A product), downgraded product (B product) and disassembled product, and the quality level of the battery cell used by the household energy storage battery manufacturer is very important to the seller. The language is basically "secret", but the product application experience will vary widely.

1.3.1 Qualified products (A products): Products that meet certain quality standards, but the so-called "standards" will also be different. For small household energy storage battery(5-20KWH), it is not necessary to adopt the automotive grade standard, because it will significantly increase the cost. Generally, batteries that meet the designed capacity, voltage, self-discharge, and more than 2,000 cycles at room temperature under 100% DOD can be applied to household energy storage, but effective pairing of batteries is required.

1.3.2 Degraded products (B products), also known as A-products: it is impossible to really know the reason why they become B products. At the same time, there are many types of degraded products, which may be caused by insufficient capacity, excessive internal resistance, excessive self-discharge, poor internal moisture control, etc. Different degradation causes have different results.

1.3.3 Disassembled products: it is known as second life or old battery. They cycle life would be much less than 2000times.

For consumer, it is hard to recognize which quality level it is from appearance. After a period time of usage, Grade B or disassembled product has shorter working time, service life or other quality problems. So make sure to order the battery from reliable supplier who can assure you Grade A quality.

2. BMS(Battery Management System)

In the energy storage battery, the battery management system BMS is one of the very important components, which determines the safety, life and matching functions and performance of the battery. It can even be said that the BMS is the "brain" of the energy storage battery. As one of the core components of household energy storage batteries, how to identify or identify the quality of BMS has become a difficult problem for many businesses. In my opinion, there are nothing more than the following points:

2.1 All lithium-ion batteries need to be protected by external circuits, which is different from lead-acid batteries and nickel-metal hydride nickel-cadmium batteries. However, there are also differences in protection circuits, which are divided into hardware solution protection circuits (commonly known as: protection boards) and software intelligent control circuits (that is, what we call BMS). The function of the protection board is relatively simple. It mainly protects the lithium battery from overcharge and over discharge, overcurrent, overtemperature and short circuit. The degree of intelligence is not high, and it basically belongs to the form of passive protection. The BMS is relatively intelligent, and can calculate the battery's state of charge SOC and health state SOH, etc., and can even take the initiative to intervene after learning, and carry out effective management through monitoring data in turn. At present, in order to pursue cost, some manufacturers in the world use protection boards to passively protect energy storage batteries for more than 5Kwh, that is not acceptable for customers.

2.2 The core technology of BMS---SOX algorithm. For the state of charge SOC and health status SOH of the battery, only accurate calculation can be effectively managed, so the SOX algorithm has become one of the core technologies of BMS, especially for the lithium iron phosphate battery system that is more common for household energy storage batteries It is more difficult. The traditional algorithm is based on the method of "ampere-hour integration + voltage calibration", which is also commonly used in the world. However, for lithium iron phosphate, the accuracy of this algorithm is poor and the calibration voltage varies greatly, which leads to problems in actual use. Large errors, especially after a period of cycle use will become more and more obvious. At present, there are many kinds of algorithm technologies on the market, but few of them are actually applied. This is also one of the technical bottlenecks in the development of new fields such as new energy vehicles and energy storage.

2.3 BMS communication: In the actual use of household energy storage batteries, the energy storage battery is connected to the inverter (or charging and inverter integrated machine), in the intelligent control and management system, how to let the inverter know the energy storage The real-time status of the battery in order to better use the energy storage battery? This requires a communication protocol to solve. The so-called communication protocol is simply understood as a dialogue language agreed in advance, and there is no novel technology. However, as a BMS of an energy storage battery, how many inverters can communicate with it is very critical, because the existence of inverters in the world is much longer than that of energy storage batteries, so energy storage batteries are required to be compatible with different versions of inverters Device communication, no technical threshold but requires a lot of accumulation.

To sum up, as the two core components of household energy storage batteries, battery cells and BMS are very important in products, especially in the current world, which has brought many uncertain choices to the market, and even vicious competition. It will be a fatal blow to the entire industry, so it is necessary to standardize products including customers and manufacturers to let the market enter a healthy and orderly development path.

SUJOR offers industry-leading portable power stations for home backup, power outages and outdoor adventures. 6 Tips help you choosing a correct Portable Power Station.

Capacity

First of all, we see the capacity. A portable power station with a large capacity gives you power for almost any situation. The larger the capacity, the more runtime you will have. It means that you can stay powered on for longer. If you are looking for everyday power for everyday devices, a portable power station with smaller capacity would be okay for you. If you are in the market for emergency power or home backup during outages, please consider getting a portable power station with big expanded capacity, like ST2000,BT2000PM,BT2000SM,PT2000,PT3600.

Output

More output wattage means more power options. Get a portable power station with a high output, you can power your appliances such as fridges, dryers or power tools. SUJOR portable power stations cover big range of output wattage from 200Wh to 3600Wh. You can choose appropriate one according to your actual usage.

Portability

If you are looking for a portable power supply that is easy to transport, then portability is a must. Smaller portable power stations like GT200, GT300, GT500, BT300,BT600 are recommended. If you want higher output, you can also choose PT2000,PT3600. They have new upgraded design with two wheels at the bottom of the units. This would be convenient for you to carry 2.0Kwh and 3.6Kwh power around.

Fast Charging

When there is disaster, a portable power station which can charge up quickly would make the world different. Even if there is power outage, you do not need to wait half a day to charge up. Most of SUJOR portable power station has fast charging technology which let you safely and rapidly charge up quickly. ST2000 supports fully-charged within 2hours.

Solar Charging

If you want a renewable power supply to give you more charging convenience, portable power station with solar charging option are a must. All SUJOR portable power stations support solar charging. Customized solar charger and controller could be provided accordingly.

Battery Chemistry

Whether we call it a portable power station or a solar generator, they are all fundamentally battery-powered devices. It is important to know the battery chemistry and battery management system(BMS) that they use. SUJOR portable power station all come with high quality Grade A LiFePO4 battery cell and come with unique battery management system that regulates current, voltage and temperature at real time. The advantages for using LFP battery is the cycle life is more than 2000times comparing to NCM battery which only has 500times.

All these 6tips cover the most important things to consider when choosing a portable power station. Wish it will be helpful for you.

A power bank's built-in battery charges through an external power supply, such as a wall socket, then stores the energy in chemical form. When needed, the battery sends electrical energy to the connected device via the output port.

Copyright © Shenzhen SUJOR Energy Technology Co.,Ltd. All Rights Reserved | Sitemap