Main difference between NiMH and Lithium ion battery:

1. **Chemical Composition:**

- Nickel Metal Hydride Battery: Uses nickel-hydrogen alloy as the positive electrode material and nickel oxyhydroxide as the negative electrode material.

- Lithium ion Battery: Utilizes lithium compounds (such as lithium cobalt oxide, lithium iron phosphate, etc.) as the positive electrode and materials like graphite or lithium titanium oxide as the negative electrode.

2. **Energy Density:**

- Nickel Metal Hydride Battery: Relatively lower energy density, typically in the range of 80-120Wh/kg.

- Lithium ion Battery: Higher energy density, reaching 150-250Wh/kg or more.

3. **Charge/Discharge Efficiency:**

- Nickel Metal Hydride Battery: Lower charge/discharge efficiency, typically around 65-70%.

- Lithium ion Battery: Higher charge/discharge efficiency, generally above 90%.

4. **Self-Discharge Rate:**

- Nickel Metal Hydride Battery: Relatively higher self-discharge rate, requiring frequent recharging to prevent losses.

- Lithium ion Battery: Lower self-discharge rate, providing more stability.

5. **Cycle Life:**

- Nickel Metal Hydride Battery: Shorter cycle life, typically around 300-500 cycles.

- Lithium ion Battery: Longer cycle life, usually exceeding 500 cycles, even reaching several thousand cycles.

6. **Cost:**

- Nickel Metal Hydride Battery: Relatively lower manufacturing cost.

- Lithium ion Battery: Higher manufacturing cost, but with technological advancements and market scale, costs are gradually decreasing.

7. **Weight:**

- Nickel Metal Hydride Battery: Heavier with a relatively larger volume.

- Lithium ion Battery: Lighter weight and relatively smaller volume.

8. **Voltage:**

-NiMH battery: Nominal voltage for one NiMH battery is 1.2V.

-Lithium ion Battery: Nominal voltage for one lithium ion battery is 3.7V.

Although NiMH batteries have many shortcomings compared to lithium batteries, they still have a place in the current market due to their price advantage and the solidification of product size used by customers. At present, the main application areas of nickel hydrogen batteries include consumer electronics, 3C digital, toys, etc; Lightings: emergency lights, mining lights, lawn lights, portable solar lights, desk lights, etc; Personal care products: beauty products, electric shavers, hair clippers, electric toothbrushes, medical equipment; Game console: Xbox One, in car electronics: T-BOX, GPS positioning, tire pressure detector, driving recorder, etc; Power products: electric tools, vacuum cleaners, red wine bottle openers, etc.

1. Battery Life:

Q:What is the lifespan of a lithium battery?

A:The lifespan of a lithium battery depends on usage conditions and cycle counts, our common battery has more than 500cycle life and capacity retention about 80%.We also have long life span battery whose cycle life is 1000times and capacity retention more than 80%.

2. Charging Speed:

Q:Does your battery support fast charging?

A:Yes, our battery usually supports fast charging, the charging time would be less. While we always advise customer slow charging because slow charge is better for battery life span.

3. Battery Safety:

Q:How safe are lithium batteries, and what precautions are in place?

A:Lithium batteries are inherently safe, but precautions should be taken to prevent overcharging, over discharging, and exposure to high temperatures. That’s why all lithium batteries should have PCM. We will customize PCM for customers according to their usage requirement, condition and battery dimension.

4. Charge Cycles:

Q:What is the cycle life of your lithium battery?

A:Our common battery has more than 500cycle life and capacity retention about 80%.We also have long life span battery whose cycle life is 1000times and capacity retention more than 80%.

5. Temperature Impact:

Q:How does high or low temperature affect the battery?

A:For common battery, high temperatures accelerate capacity degradation, while low temperatures may affect battery performance. It is recommended to use the battery within the specified temperature range.

We have special wide temperature, low temperature and wide temperature battery which can work at extremely tough environment. Please contact us for more information.

6. Storage Conditions:

Q:What are the recommended storage conditions for the battery during long periods of inactivity?

A:For long periods of storage, it is advisable to store the battery in a dry, cool place and maintain 40%~60% charge level. The best storage temp. is 23±2℃. The best humidity is 60±15%. We advise customers charge the battery at least once every half one year.

7. Charging Duration:

Q:How long does it take to fully charge the battery?

A:Charging time depends on the charger power and battery capacity, typically ranging from a few hours to a day. What needs to be considered is the power loss during the charging process, with charging time=charging capacity/charging current * (1.2-1.5). The coefficient of 1.2-1.5 here is caused by the efficiency of the charger and the loss of the charging circuit.

8. Capacity Degradation:

Q:Does the battery capacity degrade over time?

A:Yes, over time, battery capacity gradually decreases, which is a normal occurrence.

9. Operating Conditions:

Q:What are the recommended operating conditions for the battery?

A:Generally the battery discharge at -20~+60℃ and charge at 0~45℃.Humidity suggested at 45-75%RH.

10. Recycling and Disposal:

Q:How should the battery be recycled or disposed of after reaching the end of its life?

A:After the battery reaches the end of its life, it should be recycled or disposed of according to local regulations to minimize environmental impact.

11. Q: Before we provide customized solution and quotation, what should customers provide?

A: Before we provide you customized solution and quotation, please provide information as below:

Battery type: NiMh, Lithium polymer, Lithium ion or LiFePO4 battery? Or you can tell us battery voltage, capacity and dimension. If you want a battery pack or lithium battery with PCM and wire/connector, please advise us what is the application name, cut-off discharge voltage, pulse&continuous working current, part number for wire&connector, wire length,ect.

So we can customize best PCM or BMS for you. The more details you provide, the better solution we will provide for you.

We purchase rechargeable batteries mainly to maximize their long-term use, and the storage and maintenance of batteries are crucial for extending their service life. NiMH batteries are rechargeable batteries, which are widely used in electric toys, model remotes, vacuum cleaners, power tools, electric toothbrushes, electric shavers, industrial electronics, etc. due to their wide variety, low price, excellent performance, environmental protection. But how should NiMH batteries be stored when not in use? Next, let's talk about how to store NiMH batteries, what are the storage conditions and precautions?

What are the storage conditions and precautions for NiMH batteries

1. Pay attention to distinguishing battery types

When storing batteries, the type of battery is crucial. Ensure that they are separated according to production time and manufacturing. The reason is that batteries from different manufacturers placed together may cause damage, begin to leak, or react with each other.

2. Check the battery packaging

If we purchase new rechargeable batteries and do not immediately use them, please leave them in their original packaging. This can prevent the battery from coming into contact with other metals, as when the battery comes into contact with the metal, they begin to conduct electricity. Please note: Do not store the battery in a metal container, please use a battery box or plastic box. Avoid putting coins or other metals in the same box as the battery. The positive terminal of any storage battery should not come into contact with the negative terminal. If the isolation of the positive and negative terminals cannot be ensured, please cover the terminals with tape or plastic caps.

3. Charging conditions

Before storage, please make sure to check the battery level. According to testing, the optimal condition for storing NiMH batteries is around 80% of the battery level. If you plan to not use them for a few months or longer, it is best to store them when fully charged. Please note: Avoid storing NiMH batteries with 0% battery capacity. If the storage time is relatively short (such as a few days), you can store them in a low battery or empty state. Due to the self discharge of NiMH batteries, it can lead to over discharge and damage the battery.

4. Temperature conditions for storage environment of NiMH batteries

When the temperature is too high, the battery will lose its charging capacity. When storing NiMH batteries, please remember that the temperature in the storage area should not be too high. Traditional NiMH batteries need to be stored at room temperature (25 ° C ± 3 ° C). Please note: Place NiMH batteries in sunlight and store them in any cool, dry room. Please remember that the battery will self discharge when placed. SUJOR's NiMH battery can maintain 85% capacity even after being stored for one year.

5. Humidity conditions for NiMH battery storage environment

High humidity is not conducive to storing electrochemical batteries. The ideal humidity level is 35% -65%. Anti steam containers are an option to keep them away from high humidity environments. Please note: Do not place the battery in the refrigerator unless recommended by the manufacturer. The reason is as follows: condensation in the refrigerator can damage the inside of the battery.

Other precautions:

l When using a new battery or for the first time after long-term storage, please fully charge the battery before use.

l Please use a dedicated charger for NiMH or NiCD batteries.

l When placing the battery into the charger, please ensure that the polarity is correct.

l When the battery is not in use, please remove it from the device.

l After long-term storage, it is recommended to charge the battery once every three months.

l Do not mix old and new batteries as it may cause over discharge.

18650 Battery Voltage is a vital parameter of 18650 Lithium Battery. To master basic knowledge of 18650 battery voltage plays an important role of scientifically charging& discharging and protecting 18650 battery. This article tries to establish 18650 battery voltage system through explaining following parameters:

1. work voltage, also called rated voltage of 18650 battery. This voltage is 3.7V, which equals voltage of Ni-Cd or Ni-MH battery in three-series configuration. Some domestic lithium battery manufacturers might design 3.6V work voltage.

2. Limit charge voltage: maximum limit to 18650 battery voltage, which is 4.2V. 18650 battery charge is a process with voltage rising from 3.7V to 4.2V. After completion of this process, continuous discharge could cause battery overcharge.

3. Discharge cutoff voltage: that is, the minimum work voltage under which continuous discharge is unsuitable. This cutoff voltage is 2.75V. if battery discharge below cutoff voltage, over discharge occurs, which could destroy 18650 battery electrode structure, cause irreversible reaction of li ions and affect 18650 battery lifetime.

Due to severe damage of overcharge and over discharge to 18650 battery, electric circuit protection is equipped on 18650 battery to automatically stop charge& discharge when upper and lower voltage limits reach.

Battery packs could be assembled with 18650 battery in series, parallel and series& parallel ways.

1. 18650 Battery Pack in parallel form: capacity equals sum of battery cell capacity; voltage is same with rated voltage of single voltage. For instance, for 18650 battery pack assembled with two 2000mAh cells in parallel, voltage is 3.7V and capacity 4400mAh.

2. 18650 battery pack in series combination: capacity remains unchanged; voltage is sum of 18650 battery cell voltage. Take 18650 battery pack in three-series form for example, voltage is 11.1V whereas capacity remains 2200mAh.

3. 18650 battery pack in series& parallel way: for example, for 18650 lithium battery Pack in three-series and two-parallel combination, voltage is 11.1V and capacity is 4400mAh.

The above 11.1V is also work voltage of 18650 after series& parallel combination. Besides, charge limit voltage and discharge cutoff voltage varies as per series number. For instance, charge limit voltage of three-series& two-parallel battery pack is 12.6V whereas cutoff voltage is 8.25V.

Therefore, different battery combination ways have generated diverse 18650 capacity. Owing to different capacity and voltage, 18650 batteries are used in more fields.

Since its birth, 18650 battery application has been rapidly expanded with technological progress and market development. Japanese companies have made remarkable contribution to expand its applications.

During 1990s, Sony was the first to declare the birth of lithium-ion battery. Since then, 18650 battery, as the earliest lithium-ion battery, had fast replaced Ni-MH battery. Thus last century, 18650 battery was completely used on portable electronic products.

Since 21st century, Lithium Battery had taken a predominant position in the portable electronic product market. Between 2004 and 2007, Sony, Panasonic, Samsung, etc focused on increasing capacity of 18650 battery from the previous 600mAh to 2900mAh. In this period, 18650 battery was mainly used on laptops.

After 2007, Japan’s Sanyo Electric used 18650 battery on emergency portable power. Afterwards, Battery Packs made up of two or more 18650 batteries was launched, bringing forth storage 18650 battery for solar power and wind power, and power supply 18650 battery for electric motorcycles and light power cars.

Due to domestic frequent contingencies, Sanyo Electric launched emergency power used for electricity cutoff caused by natural disasters. For example, battery system made up of 321 18650 batteries can continuously work two and half hours. Reconstruction after Japan’s earthquake has fully reflected use of 18650 battery.

Seeing Sanyo’s outstanding achievement on 18650 battery, Panasonic and Sony also broadened 18650 battery packs on previous laptop to household Storage Battery and EV products. In the same period, Sony developed LiFePo4 18650 battery. Panasonic, Sony and Sanyo have turned to development of high-capacity 18650 battery for electric vehicles.

Currently, 18650 battery has widely used on EV as well as cell phones, laptops, power tools, street lights. At present,Japan companies are still developing 18650 battery with capacity over 3000mAh to further expanded its use, however, it is commonly believed that 18650 battery’s R&D should be oriented on reducing its current battery cost.

Discharge cutoff voltage is a vital parameter concerning Lithium Ion Battery lifetime. Therefore, this concept meaning should be made clear.

Lithium ion battery cutoff voltage means that it is not suitable to discharge any longer if lithium ion battery Voltage reaches a certain value otherwise, partial capacity of lithium ion battery will be irreversible or even battery will be seriously damaged. Generally rated voltage of current single lithium ion battery is 3.7V and cutoff voltage 2.75V. Yet considering following two cases, manufacturers might raise cutoff voltage to 3.0V: one case is to use battery more safely; the other is relevant to specific electric devices and operating environment. Of course, on the contrary, producers may reduce cutoff voltage to 2.5V or 2.4V. There is no cutoff voltage less than 2.4V.

In case discharge operating temperature scope is -20~60℃, lithium batteries with 2.75V cutoff voltage is able to continue discharging, however discharge with voltage lower than 2.5V is not allowed because discharge loss between 2.75V to 2.5V might be partial but discharge lower than 2.5V will lead to serious damage to battery.

Lithium ion Battery Pack, often called multi-cell lithium batteries, also has cutoff voltage, which should not be less than 2.75*n (n is serial battery number). Take 6-cell lithium Battery Pack used on laptops for example, discharge cutoff voltage of this lithium battery with 3S2P combination is 2.75V*3=8.25V and 2.5V*3=7.5V is not allowed in practical use. Actually, due to high lithium-ion battery price, both single lithium battery or multi-cell lithium battery are equipped with PCM or protection IC so that batteries will send a signal to electric devices in case of reaching cutoff voltage.

Same with all rechargeable batteries, charge time for 18650 battery equals the ratio of rated capacity to charge current. However, because of internal resistance of Lithium Battery during charge, charge time of 18650 battery should consider resistance overcome factor.

As per the resistance extent, a factor has been designed as comparison value of rechargeable battery charge time. Through long-term experiment, this factor has briefly turned into a ratio of charge current to rated capacity. Thus the above 18650 battery has become: 18650 battery charge time=rated capacity/charge current*factor.

According to national standard, battery better be charged under a current not higher than 0.2C. Based on this standard, the above factor is set 1.2. In fact, due to high capacity of 18650 Lithium Battery and different features of lithium battery charger from different manufacturers, usually this factor is set 1.5 during battery charge time calculation. Basically battery chargers are designed under this theory. For example, usually 18650 battery capacity is 1800-2600mAh. On the basis of the above formula, charger choice and 18650 battery charge time (under 0.2C discharge) should be so follow:

For 1800mAh battery, approximate 7.5-hour charge time with 350mA charger (1800÷350×1.5).

For 2200mAh battery, approximate 8.25-hour charge time with 400mA charger (8.5 hrs if 350mA charger used).

For 2600mAh battery, around 7.8-hour charge time with 500mA charger (2600÷500×1.5).

Considering different charger design, there are three alternative factors: 1.2, 1.3 and 1.5. The small the factor, the shorter the charge time will be.

Practically, 18650 battery charge time is set with PCM and protection IC during design. All that customers have to do is to use under the user instruction. Besides, it would be the best to stop charging after the color change of charger indicator because overcharge arising from too long charge time will damage charger and 18650 battery.

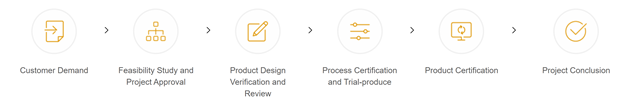

What is the process of Lithium-ion Battery Customization Process?

What parameters should customer provide for lithium ion battery customization?

1. Battery shape and size

2. Battery operating voltage and cut-off voltage

3. Battery capacity

4. Working current ,i.e. continuous and peak discharge&charge current

5. Temperature type, i.e. working environment of battery

6. Choice of PCM/BMS, ordinary or intelligent with communication

7. Input and output ports(connectors)

8. Wire type and length

We will consider material sources, battery performance, battery process, economic indicators, environmental issues before providing customer best solutions.

What service we can provide?

Battery customization:

One-to-one customization

Customize 3.7V~60V Lithium ion battery pack

Customize 10W~2000W special power supply

Customize 20W~20000W intelligent charger

Manufacturing:

Battery daily output: 350,000pcs

Multi-model, multi-batch and quick response

High quality customized battery pack fully meet personalized and diversified needs of users

Quality System:

Company ISO9001,ISO14001 approved

Battery in line with CE,CB,UL,UN38.3,KC,REACH,ROHS and other global certification

Product traceability system provides accurate data information for after-sales service.100% full inspection shipment

Logistic transportation:

Good cooperation with professional battery forwarder

Provide a variety of air shipment, ocean shipment and door to door shipment.

After-sales service:

24H response-72H proposing solutions-lifelong maintenance

Provide battery testing, battery installation, battery troubleshooting and other technical support.

Notice about lithium ion battery customization

1. Lithium battery customization is different from COTS(Commercial off-the-shelf) products. It has independent research and development&design for different products, so in the customization process, mold cost, development cost and product proofing cost required.

2. Research and development time is directly related to the new product launch. General R&D time for lithium-ion battery pack customization is about 15~30days.

Energy density refers to the amount of energy stored in a certain unit of space or mass of matter. The energy density of a battery is the average unit volume or mass of electrical energy released by the battery. The energy density of batteries is generally divided into two dimensions: weight energy density and volume energy density

What is energy density?

Energy density refers to the amount of energy stored in a certain unit of space or mass of matter. The energy density of a battery is the average unit volume or mass of electrical energy released by the battery. The energy density of batteries is generally divided into two dimensions: weight energy density and volume energy density.

Battery weight energy density=battery capacity × Discharge platform/weight, basic unit is Wh/kg (watt hours/kg)

Battery volume energy density=battery capacity × Discharge platform/volume, basic unit is Wh/L (watt hours/liter)

The higher the energy density of a battery, the more electricity stored per unit volume or weight.

How to improve energy density?

The adoption of new material systems, the precise adjustment of lithium battery structures, and the improvement of manufacturing capabilities are the three stages for R&D engineers to perform well. Below, we will explain from both individual and system dimensions.

——Single energy density mainly relies on breakthroughs in chemical systems

1. Increase battery size

Battery manufacturers can achieve the effect of battery capacity expansion by increasing the original battery size. Our most familiar example is that Tesla, a well-known electric vehicle company that was the first to use Panasonic 18650 batteries, will replace them with a new 21700 battery.

However, the phenomenon of battery cells becoming overweight or growing is only a symptom, not a cure. The ultimate solution is to find key technologies to improve energy density from the positive and negative electrode materials and electrolyte components that make up the battery cell.

2. Chemical system transformation

As mentioned earlier, the energy density of a battery is controlled by its positive and negative electrodes. Due to the fact that the energy density of negative electrode materials is much higher than that of positive electrodes, increasing energy density requires continuous upgrading of positive electrode materials.

High nickel positive electrode

Ternary materials generally refer to the nickel cobalt manganese lithium oxide family, and we can change the performance of batteries by changing the proportion of nickel, cobalt, and manganese.

In the figure, the silicon carbon negative electrode

The specific capacity of silicon based negative electrode materials can reach 4200mAh/g, which is much higher than the theoretical specific capacity of 372mAh/g of graphite negative electrode, making them a powerful substitute for graphite negative electrode.

At present, using silicon carbon composite materials to enhance the energy density of batteries has become one of the recognized development directions for lithium-ion battery negative electrode materials in the industry. Tesla's Model 3 uses silicon carbon negative electrodes.

In the future, if we want to go further and break through the single cell 350Wh/kg barrier, industry peers may need to focus on lithium metal negative electrode battery systems, but this also means changes and improvements in the entire battery manufacturing process. From several typical ternary materials, it can be seen that the proportion of nickel is increasing, while the proportion of cobalt is decreasing. The higher the nickel content, the higher the specific capacity of the battery cell. In addition, due to the scarcity of cobalt resources, increasing the proportion of nickel will reduce the use of cobalt.

3. System energy density: improving the grouping efficiency of battery packs

The grouping test of battery packs is the ability of battery "Siege Lions" to deploy individual cells and modules, which requires safety as a prerequisite and maximizes the use of every inch of space.

There are several ways to slim down battery packs.

3.1 Optimize layout structure

From the perspective of external dimensions, the internal layout of the system can be optimized to make the internal components of the battery pack more compact and efficient.

topological optimization

We achieve weight reduction design through simulation calculations while ensuring rigidity, strength, and structural reliability. Through this technology, topology optimization and morphology optimization can be achieved, ultimately helping to achieve lightweight of the battery box.

3.2 Material selection

We can choose low-density materials, such as the battery pack cover, which has gradually shifted from a traditional sheet metal cover to a composite material cover, which can reduce weight by about 35%. For the lower box of the battery pack, it has gradually shifted from a traditional sheet metal solution to an aluminum profile solution, reducing weight by about 40% and achieving significant lightweight effects.

3.3 Integrated vehicle design

The integrated design of the entire vehicle and the structural design of the entire vehicle should be considered comprehensively, and structural components should be shared and shared as much as possible, such as anti-collision design, to achieve ultimate lightweight

Batteries are a comprehensive product, and if you want to improve one aspect of performance, you may sacrifice other aspects of performance. This is the understanding foundation of battery design and development. Power batteries are specialized for vehicles, so energy density is not the only measure of battery quality.

Lithium Polymer Battery is one type of Lithium ion Battery. Compare to other lithium ion batteries, it is advantageous on high energy density, small size, thin, and high safety, cost efficient etc. It is a new type battery.

Advantage,

Ultra-thin: could be assembled in credit card.

Flexible sharp: manufacturer doesn’t need to limit to standard sharp, could make different size to fit.

Lightweight: polymer Lithium Battery doesn’t need metal case for out package.

Improve safety factor, more stable in over charge, leakage ratio low down.

Disadvantage,

Compared with primary battery, production cost for lithium polymer battery is higher. It has no standard sharp. Most of them are applicable to high capacity consume market.

Copyright © Shenzhen SUJOR Energy Technology Co.,Ltd. All Rights Reserved | Sitemap